- Welcome to The Forestry Forum.

-

Sawmill Maintenance/Repairs...

by TimW

Sawmill Maintenance/Repairs...

by TimW

[Today at 12:28:43 AM] -

Whatcha Sawin' 2024 ??

by TimW

Whatcha Sawin' 2024 ??

by TimW

[Today at 12:18:17 AM] -

ID Help

by Southside

ID Help

by Southside

[Yesterday at 10:49:22 PM] -

It's a Go! 2024 FF Pigroast....

by Old Greenhorn

It's a Go! 2024 FF Pigroast....

by Old Greenhorn

[Yesterday at 10:22:01 PM] -

Making it through another...

by Old Greenhorn

Making it through another...

by Old Greenhorn

[Yesterday at 10:15:56 PM] -

The Score Of The Day Thread...

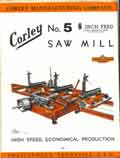

by Corley5

The Score Of The Day Thread...

by Corley5

[Yesterday at 09:44:27 PM] -

More Giant Sequoias In England...

by chep

More Giant Sequoias In England...

by chep

[Yesterday at 08:56:03 PM] -

Sawing Project 2024

by Jeff

Sawing Project 2024

by Jeff

[Yesterday at 08:50:58 PM] -

Survivor

by Magicman

Survivor

by Magicman

[Yesterday at 08:46:23 PM] -

Where to best use knottier...

by Don P

Where to best use knottier...

by Don P

[Yesterday at 07:58:16 PM] -

What speed are the Lucas blades...

by Grower

What speed are the Lucas blades...

by Grower

[Yesterday at 07:53:37 PM] -

New starter motor needed soon...

by Magicman

New starter motor needed soon...

by Magicman

[Yesterday at 07:34:06 PM] -

Another ID question

by SwampDonkey

Another ID question

by SwampDonkey

[Yesterday at 06:59:22 PM] -

Pro Mac 610 Start/Stop Switch...

by sawguy21

Pro Mac 610 Start/Stop Switch...

by sawguy21

[Yesterday at 06:50:34 PM] -

Francis Scott Key Bridge Collapses...

by gspren

Francis Scott Key Bridge Collapses...

by gspren

[Yesterday at 06:50:34 PM]

Do you have trees to grow? Logs to saw? A forest to manage? Chainsaws to fix? A sawmill to purchase or maintain? Timber related business to run? Lumber to dry? Trees or plants to identify? A cabin to build? Are you hungry and like FOOD?

Or would you just like to pull up a stump and visit with a friend?

If any of these and a multitude of other topics apply, then The Forestry Forum is the

place for you.

Thank-You to our Contributing Shameless Commerce Members

- Carolina Custom Cut LLC

- Blue Harbor Refinishing

- D & S Sawmill Services

- Fether Hardwoods

- Whispering Pines Farm

- Log-Gistics. A neighborhood sawmill

- Custom Wood Fibers

- Whidbey Woodworks and Custom Milling

- Hamsley Hardwood Quality Hardwood Lumber

- Saw it Coming - Portable Sawmill Service

- Dave's Sugarhouse

- Nicholson Wood Products LLC

- Welsh Tree Service

- Terrific Timbers LLC

- A&P Sawmill LLC

- Enderby Rentals

- Quartersawnoak.com

- The Custom Sawyer

- Eastern Red CedarProducts LLC