- Welcome to The Forestry Forum.

674 Guests, 20 Users

SunnyHillFarm, Magicman, Zgin, livemusic, Oakandstone, Gearbox, Old Greenhorn, bigtim, OH logger, old guy, Hilltop366, Mooseherder, sprucebunny, trapper, Texas Ranger, trimguy, dnash, TroyC, BlackberryPines, Ray Edge

SunnyHillFarm, Magicman, Zgin, livemusic, Oakandstone, Gearbox, Old Greenhorn, bigtim, OH logger, old guy, Hilltop366, Mooseherder, sprucebunny, trapper, Texas Ranger, trimguy, dnash, TroyC, BlackberryPines, Ray Edge

Recent posts

#1

Sawmills and Milling / Re: buying 1st saw mill(?)

Last post by thecfarm - Today at 09:00:57 PMYou will like sawing!!!

#2

Sawmills and Milling / Re: Whatcha Sawin' 2024 ??

Last post by WV Sawmiller - Today at 08:41:23 PMTesting photo gallery

No joy. I was able to add a new album which did not work last time. I added a photo to the album but can't see how to get it from the album to this thread. Can't find album under Drag and drop. Go straight to Gallery, click on the picture and double click and try control C for copy but that is not the ticket.

No joy. I was able to add a new album which did not work last time. I added a photo to the album but can't see how to get it from the album to this thread. Can't find album under Drag and drop. Go straight to Gallery, click on the picture and double click and try control C for copy but that is not the ticket.

#3

Drying and Processing / Re: Air Drying vs Kiln Drying

Last post by Don P - Today at 08:39:47 PMI mixed curcumin (turmeric) in a solvent and painted that on the fresh cut ends of boards I had rolled borate on about a year before. I wanted to see how deep the mix was penetrating. Boron and curcumin make rosocyanine, a bright red compound.

Nisus sells an indicator solution, that is it. If you read some of the test reports from the RTA, Railroad Tie Association, they were using the same indicator to test long term efficacy of borate in ties.

Nisus sells an indicator solution, that is it. If you read some of the test reports from the RTA, Railroad Tie Association, they were using the same indicator to test long term efficacy of borate in ties.

#4

Sawmills and Milling / Re: buying 1st saw mill(?)

Last post by 47sawdust - Today at 08:20:12 PMNo need to rush it,the gas won't go bad.

#5

General Board / Re: Making it through another ...

Last post by Old Greenhorn - Today at 08:14:52 PMRes, it sounds strange to admit this but I really wish I had some competition so I could refer clients to them and take a little load off of me when I need it. Either that, or I am going to have to run an apprentice program, getting some of these buyers to come in and work with me for a day and get a discount on their logs, which is an idea I am working on in my little head.

------------------------------------------

So Monday was full out on the trailer, discussed in that other thread, yesterday was pretty much also the same, but with distractions on show planning and looking over where I stand. The weather was SO nice that I may have been distracted and just spent some time sitting and thinking of my way forward.

Today was the monthly food shopping trip, which kills a half day. I got and hour or two messing around before we went though and finally got the work around 1pm. I started in on the trailer re-doing the securing system, got that done, did some decal work, then started in the shop and built up a Loginator for a client that is hopefully picking up his logs Friday. By the time I finished that, it was quitting time, but I need to keep moving on merch. I have a set of park bench legs and back. I figured I MIGHT be able to do the wood up and re-finish the legs and back in time for this show if I get my act together. I have about 5 projects/products I would like to finish and get ready for the show, which I figure I have about 7 more days to do. I'd also like to make some lower end benches to have on hand, which adds to the load.

It's not all going to happen, I know, but I'd like to give it my best shot and see how far I can get. The park bench is not likely to happen because it requires a painting technique I have no idea how to do, or where to look for help, but I will work on that too. Tomorrow is a rain out, so I'll heat up the shop and dig into it.

It's another day, let's see what I can pull off, or not while everyone is headed to The PrOject.

Edit to add: I came in just in time tonight to call in my 'annual" order to Madsen's. I was cash poor last year in the fall when I usually do this and let it slide. But I need some new jeans, a clean new shirt, and the the usual supplies that I am running out of like wedges, flagging, crayons, socks, etc. So it was nice to be able to just do that, and hopefully I will have some newer clothes for the shows as well as replacement supplies in my tool bags for the work. I like buying from Madsen's but they are still very old school. No emails, no tracking numbers, no online orders. You just call and talk to a salesperson, he can answer ANY questions to you have about the gear, and then he says "OK we'll get that right off to you" but I have no idea what the total cost is or what the shipping cost is. I just have to trust them. But I'm OK with that. I actually wish we had more 'Madsen's' in this world instead of Amazon's.

------------------------------------------

So Monday was full out on the trailer, discussed in that other thread, yesterday was pretty much also the same, but with distractions on show planning and looking over where I stand. The weather was SO nice that I may have been distracted and just spent some time sitting and thinking of my way forward.

Today was the monthly food shopping trip, which kills a half day. I got and hour or two messing around before we went though and finally got the work around 1pm. I started in on the trailer re-doing the securing system, got that done, did some decal work, then started in the shop and built up a Loginator for a client that is hopefully picking up his logs Friday. By the time I finished that, it was quitting time, but I need to keep moving on merch. I have a set of park bench legs and back. I figured I MIGHT be able to do the wood up and re-finish the legs and back in time for this show if I get my act together. I have about 5 projects/products I would like to finish and get ready for the show, which I figure I have about 7 more days to do. I'd also like to make some lower end benches to have on hand, which adds to the load.

It's not all going to happen, I know, but I'd like to give it my best shot and see how far I can get. The park bench is not likely to happen because it requires a painting technique I have no idea how to do, or where to look for help, but I will work on that too. Tomorrow is a rain out, so I'll heat up the shop and dig into it.

It's another day, let's see what I can pull off, or not while everyone is headed to The PrOject.

Edit to add: I came in just in time tonight to call in my 'annual" order to Madsen's. I was cash poor last year in the fall when I usually do this and let it slide. But I need some new jeans, a clean new shirt, and the the usual supplies that I am running out of like wedges, flagging, crayons, socks, etc. So it was nice to be able to just do that, and hopefully I will have some newer clothes for the shows as well as replacement supplies in my tool bags for the work. I like buying from Madsen's but they are still very old school. No emails, no tracking numbers, no online orders. You just call and talk to a salesperson, he can answer ANY questions to you have about the gear, and then he says "OK we'll get that right off to you" but I have no idea what the total cost is or what the shipping cost is. I just have to trust them. But I'm OK with that. I actually wish we had more 'Madsen's' in this world instead of Amazon's.

#6

Sawmills and Milling / Re: Opinions on 2016 Wood-Mize...

Last post by GAB - Today at 08:07:27 PMQuote from: Hwy 90 Sawmill on Yesterday at 06:39:02 AMThe deal is done. I spoke with the gentleman selling the LT50 yesterday morning and we agreed on $42k. I am more that satisfied with that price.When you charge by the hour some customers plan on having help to get the sawing done as it is costing them more if they are slow. I find that there is more customer incentive when charging by the hour.

I have a potential buyer driving over from Jacksonville, FL today to look at my LT35 HDG25. I am asking $30k for it.

Thanks for everyone's input.

I know there are threads in here discussing pros/cons of charging by the BF or by the hour (we currently charge $125/hr, includes the sawyer and a helper), so I am going to find them and see if we should switch to the BF since we now will have a mill that will increase production.

GAB

#7

General Woodworking / Re: Anti fogging face shields,...

Last post by scsmith42 - Today at 07:52:00 PMI use one them for milling, and they work as advertised. It's nice to keep the sawdust out of my face.

#8

General Board / Re: Enclosed Trailers: Tips an...

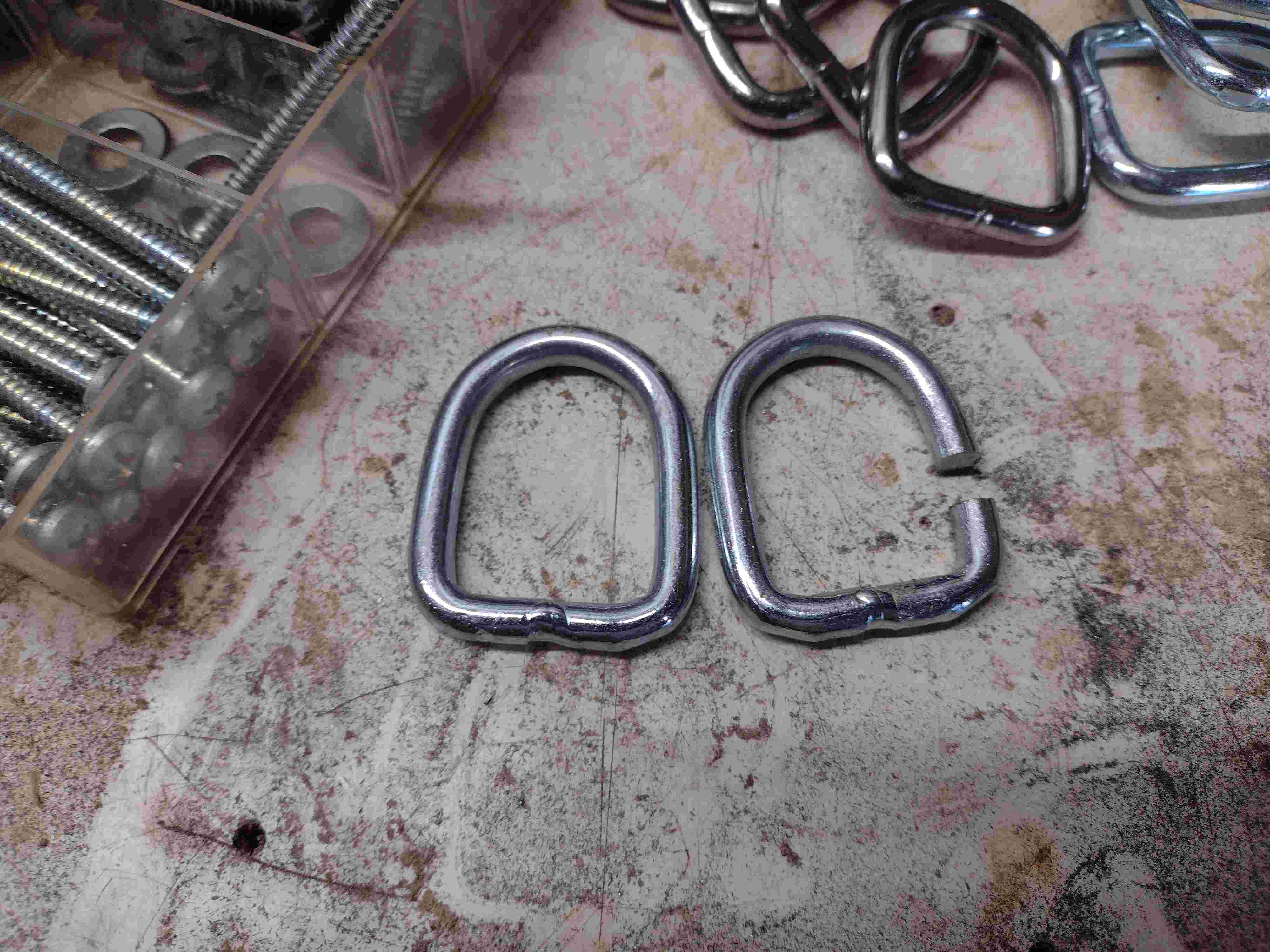

Last post by Old Greenhorn - Today at 07:42:17 PMWell after my last update I spent an hour or more searching for hooks to replace those d-rings. I finally gave up. As I was getting into bed, still annoyed by my failure, I realized I could just cut a slot in the ones I have. The material will handle the load, which really isn't that great anyway.

So I got out there early this morning and fired up my (yet unused) cutoff disc and made one up. It's very simple, should have thought of it sooner

.

I didn't even have to try it to know it would do the job. Problem solved, but I had to go off on family stuff for several hours and I picked up more d-rings while we were out.

When we got back I started removing all the d-rings in the center sections, cutting the slot, then putting them back. It took a couple of hours to re-rig it all. Still more fine tuning to do over time. I also nested in a few stools as was suggested. Everything is high and tight. I need to get more screws to hang more ring/hooks, but that's for another day. I also put the artwork on the back door before the rain came in and put on some reflective safety strips on the back too, feeling it was pretty dark and hard to see., but I have to transition back to shop work and make some product and other 'stuff'.

It's coming down to small details now and none too soon.

So I got out there early this morning and fired up my (yet unused) cutoff disc and made one up. It's very simple, should have thought of it sooner

.

I didn't even have to try it to know it would do the job. Problem solved, but I had to go off on family stuff for several hours and I picked up more d-rings while we were out.

When we got back I started removing all the d-rings in the center sections, cutting the slot, then putting them back. It took a couple of hours to re-rig it all. Still more fine tuning to do over time. I also nested in a few stools as was suggested. Everything is high and tight. I need to get more screws to hang more ring/hooks, but that's for another day. I also put the artwork on the back door before the rain came in and put on some reflective safety strips on the back too, feeling it was pretty dark and hard to see., but I have to transition back to shop work and make some product and other 'stuff'.

It's coming down to small details now and none too soon.

#9

Forestry and Logging / Re: Selling logs to a small ti...

Last post by Peter Drouin - Today at 07:31:10 PMThe big mills around here only want 16' 14' some 12' no 10s or 8s. And they don't care how crooked they are.

Get a subscription to the Log Street Journal. It will give you an idea of what going on. on price. Or maybe online. It's for the Northeast for the most part. But it might help. Good luck.

Get a subscription to the Log Street Journal. It will give you an idea of what going on. on price. Or maybe online. It's for the Northeast for the most part. But it might help. Good luck.

#10

Sawmills and Milling / Re: Swing mill build questions

Last post by Woodside Kai - Today at 07:12:47 PMA climb cut is when the saw blade is rotating the same direction as if it were rolling along the log. ( think clockwise rotating blade feeding from left to right)

The reason it is a no no is the blade will pull itself into the log rapidly and disaster will strike. If the blade is rotating the opposite direction it will pull itself out of the cut if no feed force is applied.

Which direction your blade swings is what will determine if your blade will rotate the correct way to edge on the return pass of the carriage.

The reason it is a no no is the blade will pull itself into the log rapidly and disaster will strike. If the blade is rotating the opposite direction it will pull itself out of the cut if no feed force is applied.

Which direction your blade swings is what will determine if your blade will rotate the correct way to edge on the return pass of the carriage.